Subs are generally part of most drill strings and have two main functions:

To crossover connections

To extend the life of a more expensive drill stem item and/or as a disposable component

This means that subs have to be manufactured from selected bars of alloy steel, heat-treated to provide the strength and toughness required to carry the entire weight of the drill string or to withstand high torque differentials. Generally, subs exceed API specifications for drill pipe tool joint mechanical properties.

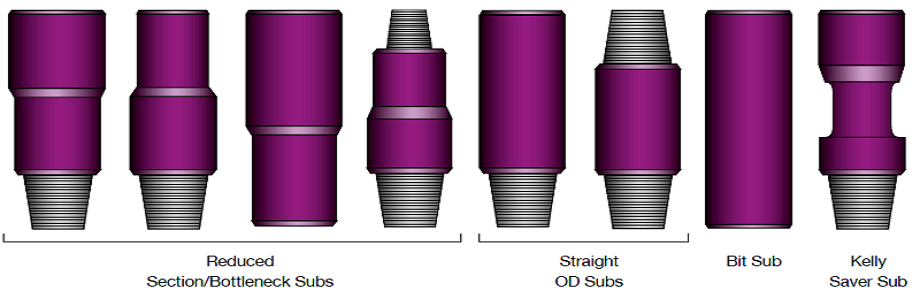

Subs are classified into four main categories:

Bit subsor crossover subs are used to connect the drill bit to the first piece of BHA equipment or to crossover connections in the drill string. Drill bits are manufactured with a pin, making make-up impossible without a bit sub.

Crossover subları, sondaj dizisindeki farklı bağlantı tiplerini birbirine bağlamak için kullanılır.

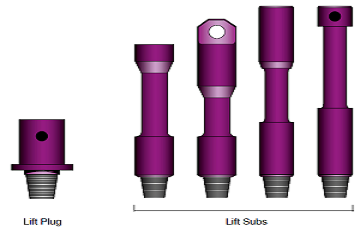

Lift subsor handling subs are used to lift BHA components from the catwalk to the rig floor.

Top drive subsor saver subs serve as the sacrificial element between the drill string and the top drive, reducing repair and maintenance costs.

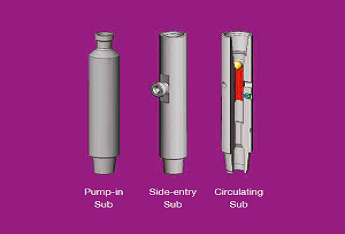

Workover subsor circulating subs are used to limit the allowable fluid-circulation rates.