COMMAND-SMFI drill collars are thick-walled tubulars machined from solid steel bars and manufactured to specifications to meet and/or exceed API or NS-1 requirements. The quality of the heat treatment is critical in the production of raw materials and must be uniform and deep enough through the thickness of the bar to ensure the mechanical properties.

Drill collars are used as a component of the bottom-hole assembly (BHA) and provide the following:

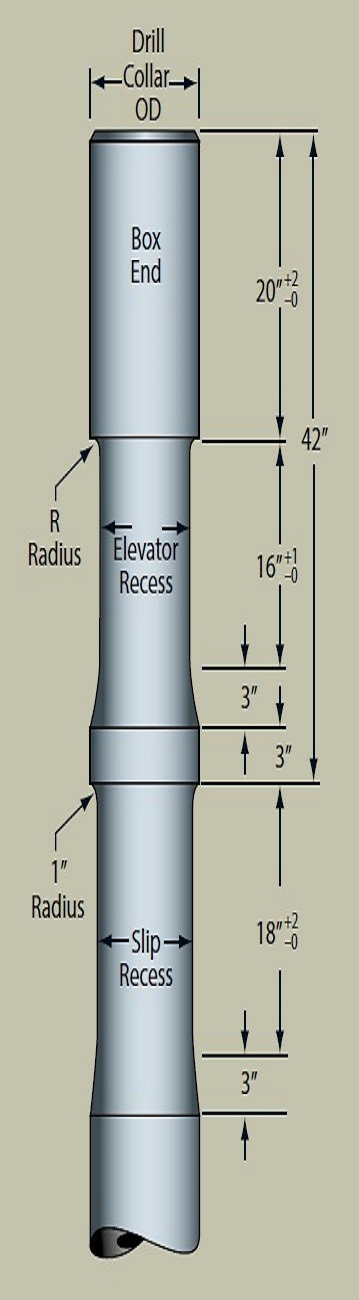

PRODUCT RANGE AND FEATURES

Standard

Options